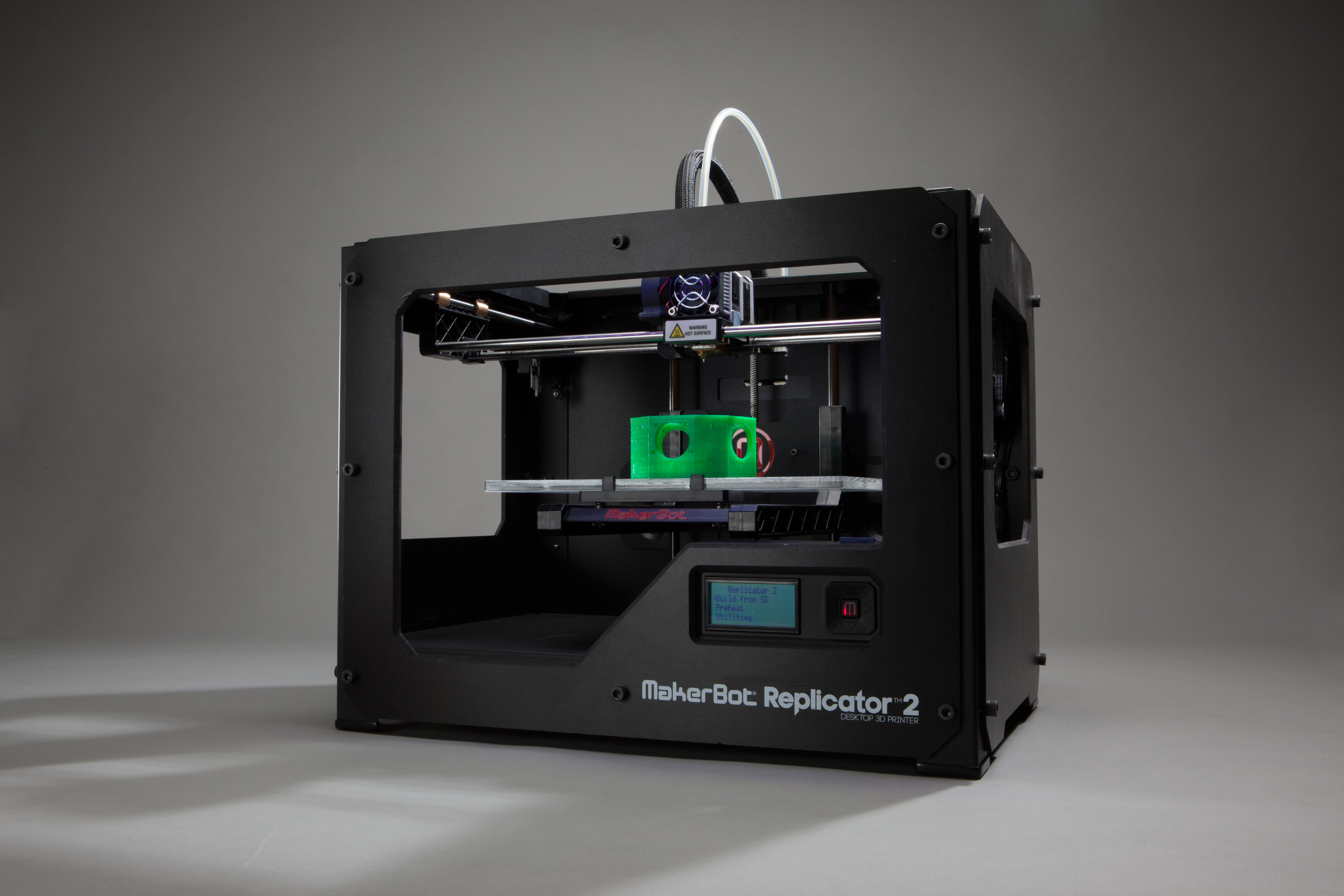

The theater department was able to purchase a 3D printer last year with the help of Kick Starter, a popular fundraising site.

The printer cost $350 which was, “…at the time, a considerable savings,” according Jeff Gress, technical director and designer of theater.

“Our program uses such a wide variety of technologies and teaching tools that it was a natural for us,” Gress said.

The theater department utilizes many items for props, and usually tries to buy as many as they can from thrift stores. But with the new printer, students can create custom props and costume detail items.

“I’m curious to see what we can develop for our last show, CATS, in terms of costume accessories and decorative items for the hoarder/cat lady house we are setting the show in,” Gress said.

The machine can print anything approximately 15 inches cubed. The material it uses to print these objects is inexpensive and there are many object designs for free on the internet.

Unlike conventional 2D printers, the main limiting factor is not materials, but time.

“As a low-cost, early generation printer, it uses very fine threads of material and so it takes a pretty long time to build up the objects a strand at a time,” Gress said. “It’s the kind of thing we would start first thing in the morning and hope that it finishes by the end of the evening rehearsal.”

But its not just about printing.

“[The 3D printer] is a part of a much larger discussion about how students experience learning in so many different ways here at Cap, through the theatre Program and the larger communication department,” Gress said.

Gress said he is not sure if the university is adding any new 3D printers soon.

The theater department is also working on introducing new LED lighting, and new wireless technologies for show control and design.